British style and design studio Seymourpowell has put inexpensive digital products under the highlight with Un-Made, a venture imagining 4 doable means to layout for rapid disassembly and recycling.

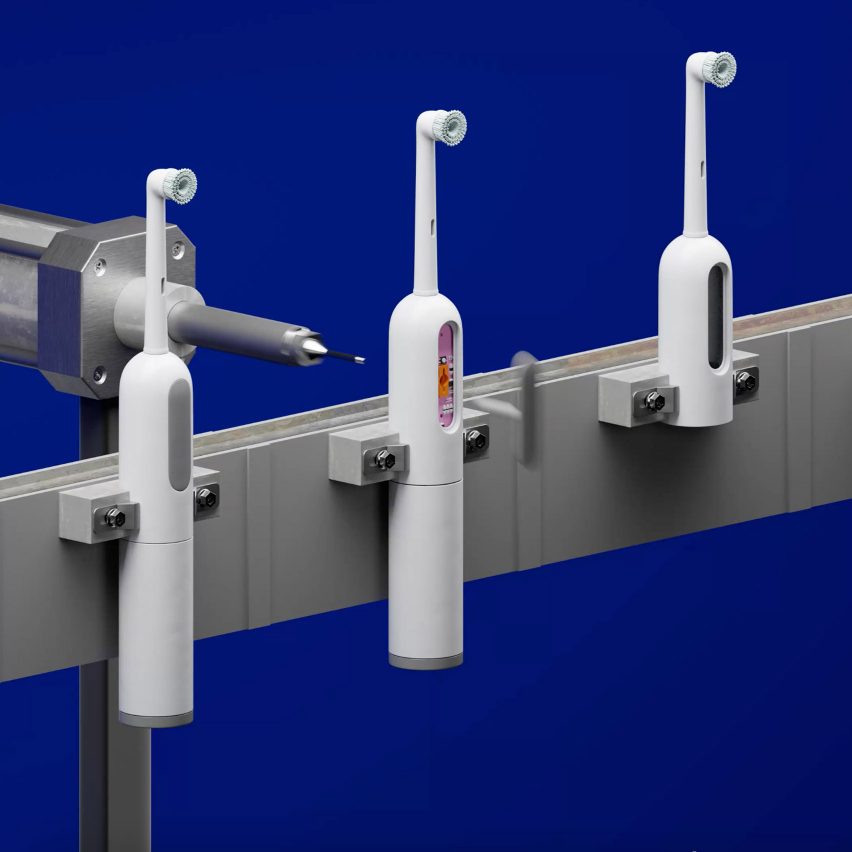

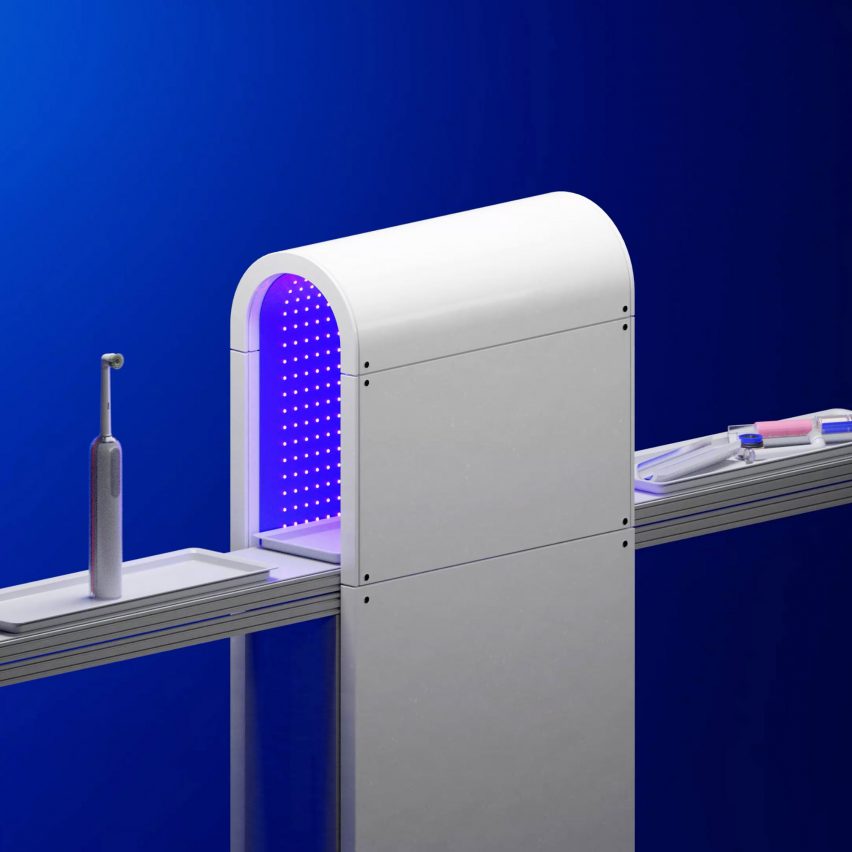

As part of the challenge, Seymourpowell devised four automatic disassembly system principles employing an electric toothbrush as an instance for their animated graphics.

Every of the mechanisms could be built into a merchandise during producing and then activated in a manufacturing facility at the end of the item’s lifetime.

The to start with Un-Created principle is a pin system. Equivalent to the action of opening a SIM card slot on a smartphone, it requires poking a pin into a little, sealed pinhole on the rear of the product or service to launch the inner elements.

The next concept is a vacuum mechanism. It entails putting the item into a vacuum, leading to closed cell foams and air-sealed attributes within it to grow and bust the exterior housing open.

3rd, there is a piston system that operates by pushing a piston by way of a cap on the bottom of a device and forcing all of the inner elements upwards until eventually they arise as a result of the leading.

The remaining concept includes employing UV glue – a style of adhesive that deactivates below ultraviolet gentle. In this thought, the product or service is put into a specially lit chamber to release the clamshell construction.

The Un-Produced undertaking was led by Eddie Hamilton, a senior industrial designer at Seymourpowell, who was pushed to make the operate soon after looking into what electrical toothbrush to obtain for himself.

“Inevitably I went for the cheap one particular, at which level Amazon smugly pointed out they’d sold 10k+ of that model past month by itself,” mentioned Hamilton.

“As an industrial designer, I expend time obsessing more than the product I’m doing work on, generally imagining of it in isolation,” he added.

“But just one issue I from time to time fail to recall or adequately photograph is the genuine scale of that products once made. 10,000 models bought per thirty day period would seem huge.”

Making use of Amazon’s bestsellers listing, Hamilton ascertained that fabric shavers, steam irons, wi-fi doorbells, wi-fi personal computer mice, electronic tyre inflators and USB-C adaptors have been all goods selling in their 1000’s each month, at a rate of much less than £20.

Whilst developing solutions so they can be repaired is important, the associated expenditure may perhaps not be a thing that buyers can justify for little things sold at this price level, Hamilton explained.

Camper unveils modular trainer “uncomplicated more than enough to assemble and disassemble by customers”

“Even if we improve societal attitudes, the base line is whether or not you need to open up that low cost toothbrush to replace a failing battery when you only compensated £24.99 for it two several years ago,” he said.

“I am optimistic for some item categories to get the ball rolling, specifically high-priced and bulky goods. But I am also a realist that we want alternative methods adjacent to mend. This is where by we should style for disassembly.”

In Hamilton’s check out, disassembly and recycling is a worthy “following greatest choice” to repair for more affordable objects, as it retains the products in a round content movement.

The Un-Produced layout group took inspiration from Agency of Design’s Style and design Out Waste task, which seemed at a few approaches for keeping a toaster out of landfill. But they specially desired to examine just how successful the disassembly method could be built as a result of automation.

The less expensive and less complicated the course of action, they say, the much more drive there is for companies to pursue this strategy and get better the factors and materials inside their devices.

“A massive section of the explanation e-waste ends up in landfill is simply because of product or service complexity and the inherent challenges included in their disassembly,” Seymourpowell lead designer Alex Pearce explained to Dezeen.

“To day, for the reason that e-squander has been deemed also time-consuming and high-priced to disassemble – there has been no (business) incentive potent plenty of to make it a practical selection.”

The components inside even low cost equipment are valuable, Pearce factors out, notably when there are source shortages or when it will come to scarce-earth minerals.

“When you think about that more gold exists within just a ton of e-squander than inside of a ton of gold ore dug from the floor, a clear-cut economic vital gets apparent for companies who are able to recuperate and reuse these elements,” said Pearce.

Seymourpowell imagines disassembly getting location both at the manufacturer’s services adhering to a just take-again course of action, or possibly at a public recycling centre if disassembly processes have been sufficiently standardised.

The London-dependent studio is recognized for its revolutionary merchandise and transportation types, as effectively as concepts that obstacle existing norms. New projects from the studio have integrated the two-in-a single reusable Bottlecup and a spaceship cabin for Virgin Galactic.